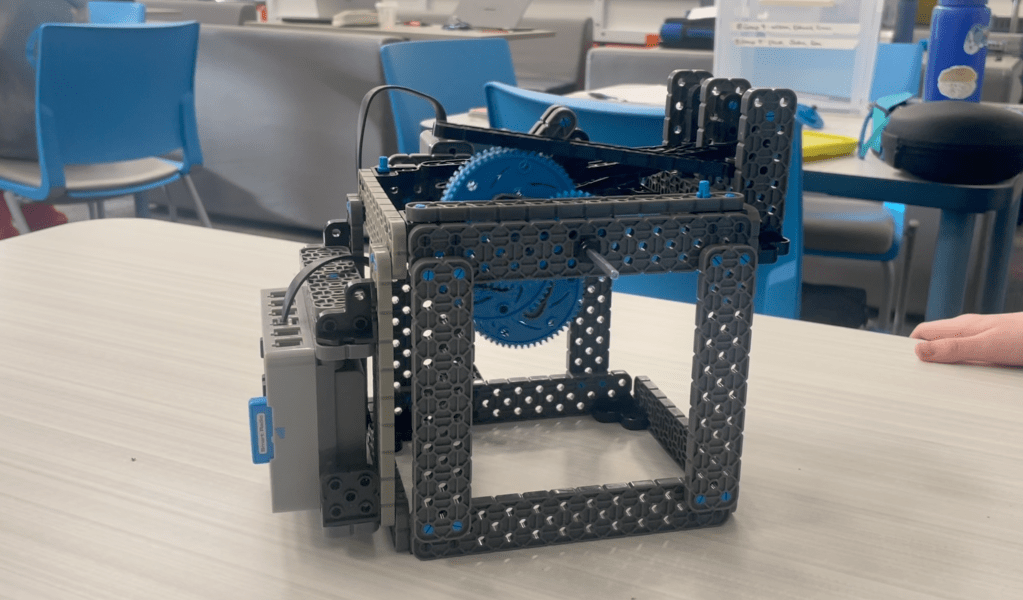

Our SW Junior High option PC Remix is now in the assembly stage of the mechanical keyboard project. This year, students could choose between two 3D-printed case styles: a thin, two-piece low-profile case or a larger, one-piece high-profile case. Our 3D printers were running nonstop in September to produce these custom cases in a variety of colors selected by the students.

To support the project, our high school Fab Lab laser-cut 100 clear plexiglass alignment plates. These plates hold the keys in place while also allowing the LED lights to shine through.

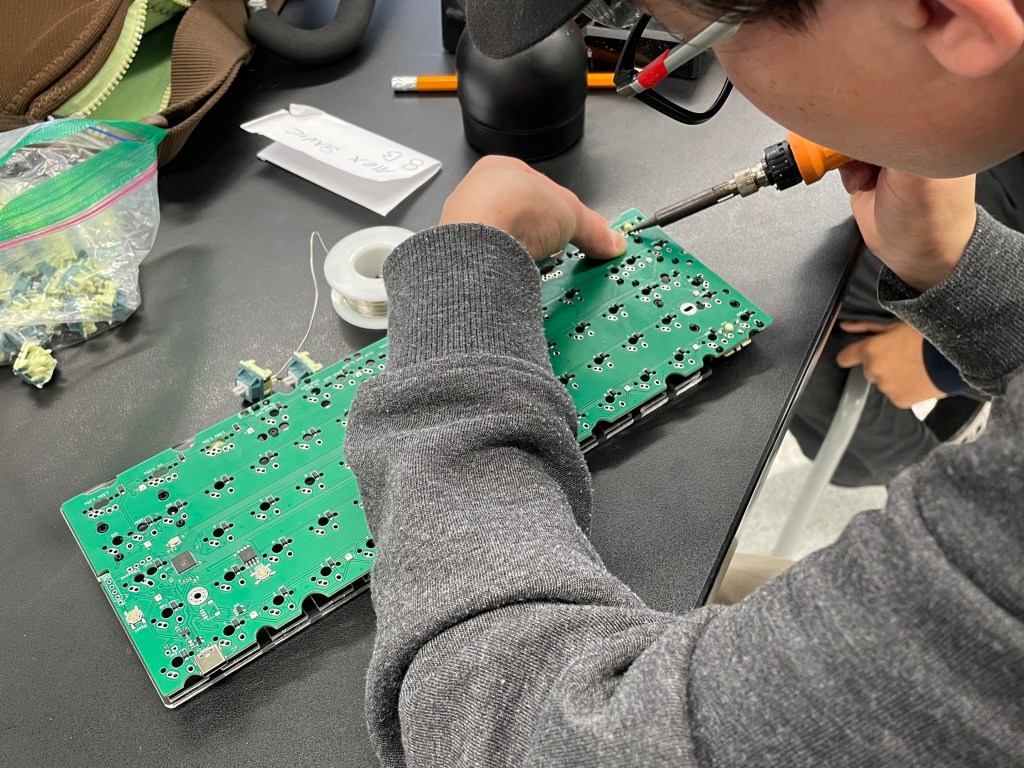

Students then selected colored keycaps from our collection, which will be installed on the switches once each one is soldered to the PCB (Printed Circuit Board). Working in the Digital Media Lab with Mr. Jensen and Mr. Christiansen, students practiced soldering—each of the 60 keys requires two solder points, providing plenty of opportunity to refine their technique.

Once the switches and stabilizers were in place, students mounted the circuit board and alignment plate into their 3D-printed cases. With the keycaps installed, the keyboards were ready to plug in and use. The circuit boards include built-in LEDs, which students can program with a companion application to customize their lighting effects.

These customizable keyboards have brought a lot of creativity to the project. Some students even designed and 3D-printed their own unique keycaps to make their keyboards truly stand out.

This post was enhanced with ChatGpt with the prompt: “Clean up this blog post for flow and grammar”