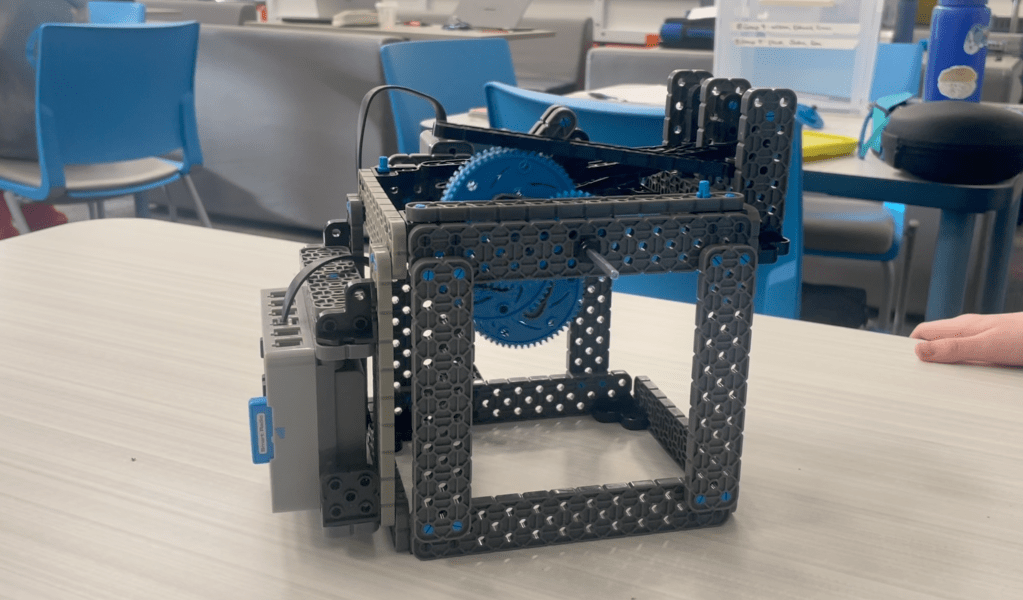

3D printing is a technology that lets you create real, three-dimensional objects from a digital design.

First, you create a model using computer software, like TinkerCad, Blender or Fusion360. Our students begin with TinkerCad in our grade 7 Introduction to Design and Engineering course and continue in their options and core courses with more sophisticated models and software.

Keaston K. Grade 9

After the model is created, it is exported to a different piece of software called a Slicer. Slicing a 3D model for 3D printing is the process of converting a digital 3D design into a format that a 3D printer can understand. This is done using slicing software, such as Ultimaker Cura. The software analyzes the 3D model and divides it into hundreds or thousands of horizontal layers, generating specific instructions for the printer to follow. These instructions include details like the path the printer’s nozzle should take, the amount of material to extrude, and the temperature settings. By slicing the model, the printer can build it layer by layer, creating the final object from the bottom up.

People use 3D printing for all sorts of things, like creating prototypes for products, designing custom tools, or even creating parts for vehicles. Currently our Biomedical Engineering classes are 3D printing ergonomic accessories for everyday items.

Keaston K. Grade 9